Advertisement

Help Keep Boards Alive. Support us by going ad free today. See here: https://subscriptions.boards.ie/.

If we do not hit our goal we will be forced to close the site.

Current status: https://keepboardsalive.com/

Annual subs are best for most impact. If you are still undecided on going Ad Free - you can also donate using the Paypal Donate option. All contribution helps. Thank you.

If we do not hit our goal we will be forced to close the site.

Current status: https://keepboardsalive.com/

Annual subs are best for most impact. If you are still undecided on going Ad Free - you can also donate using the Paypal Donate option. All contribution helps. Thank you.

https://www.boards.ie/group/1878-subscribers-forum

Private Group for paid up members of Boards.ie. Join the club.

Private Group for paid up members of Boards.ie. Join the club.

Hi all, please see this major site announcement: https://www.boards.ie/discussion/2058427594/boards-ie-2026

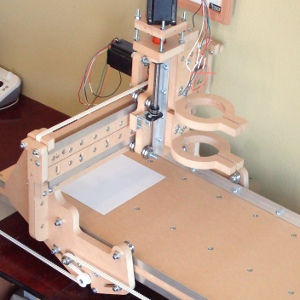

DIY Woodworking CNC machine

-

02-12-2010 01:45PM#1

Comments

-

-

-

-

-

-

Advertisement

-

-

-

Advertisement

(Image from

(Image from  (from ProtoTools above)

(from ProtoTools above)